Add to Cart

TC Radial Bearings are designed for high performance applications. They are a type of bearing used to allow for rotating motion to transfer between two points of rotation. The bearings come in different sizes and have a central bearing gap, where the balls or rollers are located. The components of the TC Radial Bearing are usually constructed from high-grade steel and can also come with synthetic lubricants or a combination of both. This type of bearing provides superior strength and resistance to corrosive elements, making it suitable for applications with high loads or in harsh environments. TC Radial Bearings also come with a variety of sealing and noise reduction options, extending the life of the bearing.

Major Product Lines

Product Features

High Load Capacity: TC radial bearings are designed to handle high loads and shock loads, making them ideal for applications that require high load capacity.

Low Maintenance: TC radial bearings require minimal maintenance and lubrication, making them ideal for applications that require less maintenance.

High Durability: TC radial bearings are designed for long life and are highly resistant to wear and fatigue.

Low Friction: TC radial bearings are designed with low friction and low wear characteristics, making them ideal for applications that require low friction.

High Speed: TC radial bearings are designed to operate at high speeds, making them ideal for applications that require high-speed performance.

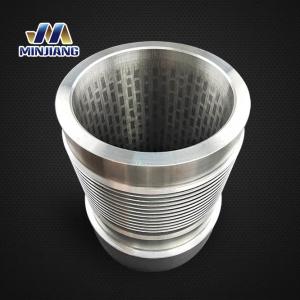

Product Structure

Quality Guarantee

At TC Radial Bearing, we strive to provide superior quality products and services while delivering outstanding customer service. We understand that precision and reliability are paramount for our customers and that is why we only utilize the best materials and production methods. Our bearings are designed to perform dependably in a variety of applications and all products are subjected to extensive testing. Our steel and components are of the best quality and all our bearings provide superior performance and durability. In addition to our exceptional products, we also offer installation, maintenance, and repair services. We are dedicated to our customers and promise satisfaction with each purchase. If, for any reason, you are not satisfied with your purchase, our friendly customer service staff will be there to assist you. At TC Radial Bearing, we want to ensure our customers receive the best products and services.

FAQ

1. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

2. Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

3. Q: How do you guarantee your quality?

A: Material selection and hardness survey are critical for product quality. We were formally engaged in forging and had a good command of the mechanics and properties of different tool steels. Inspection of incoming materials is furthermore well taken care of. Long-term raw providers physically near to us, help make us more competitive, ensured quality.